UROLASE+

NEW GENERATION OF THULIUM

FIBER LASERS

SAFETY.INNOVATION.

EFFICIENCY.

THE UROLASE+ LASER SERIES IS A NEW GENERATION OF THULIUM FIBER LASERS EQUIPPED WITH A TISSUE DETECTION SENSOR THAT AIMS TO ENSURE MAXIMUM SAFETY DURING SURGICAL PROCEDURES.

Download the Urolase+ brochure

REVOLUTION IN LITHOTRIPSY

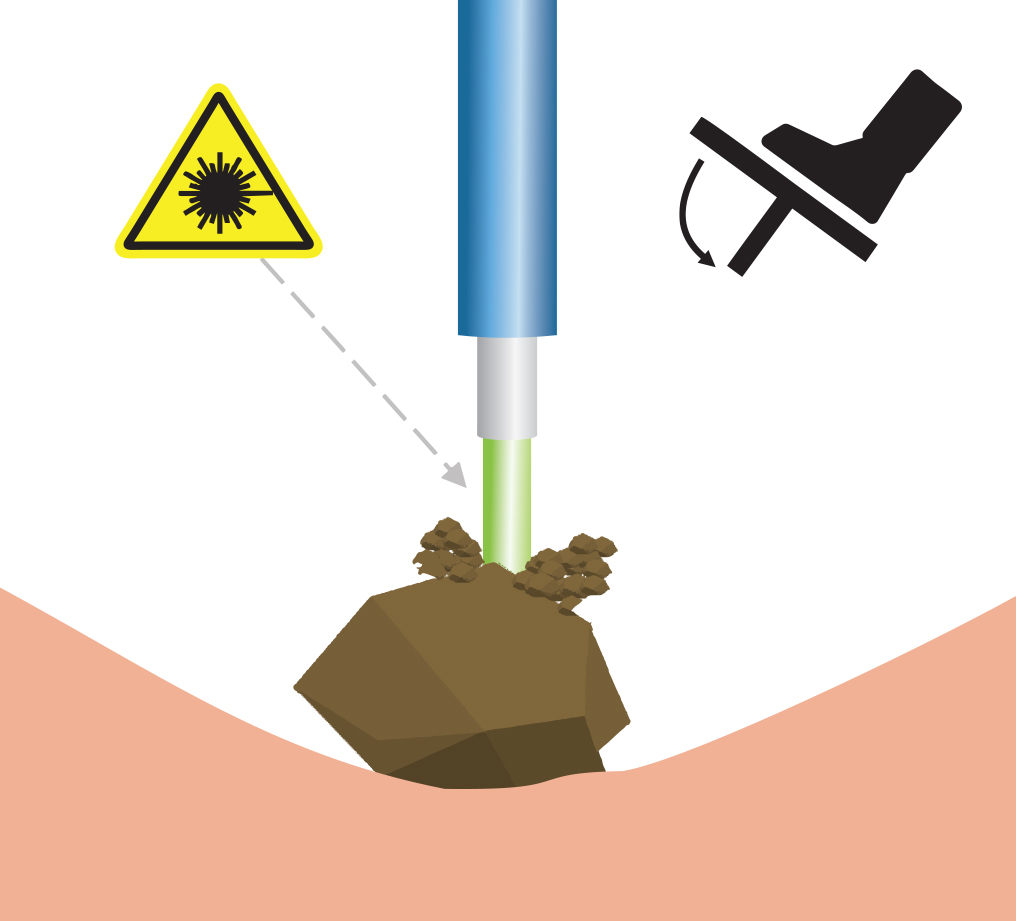

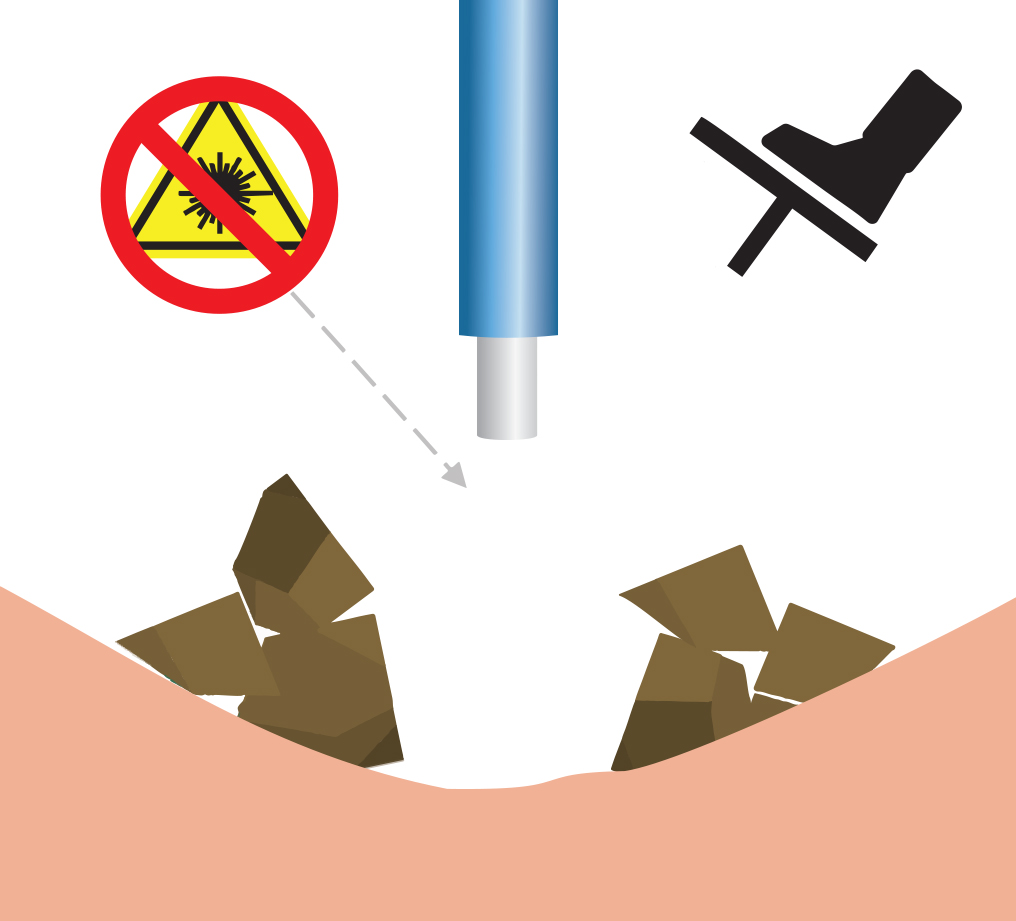

Tissue sensor is an innovative development of IRE-Polus aimed at absolute maximization of safety during stone crushing. This technology is designed to strengthen the developing trend towards endoscopic treatment of urolithiasis.

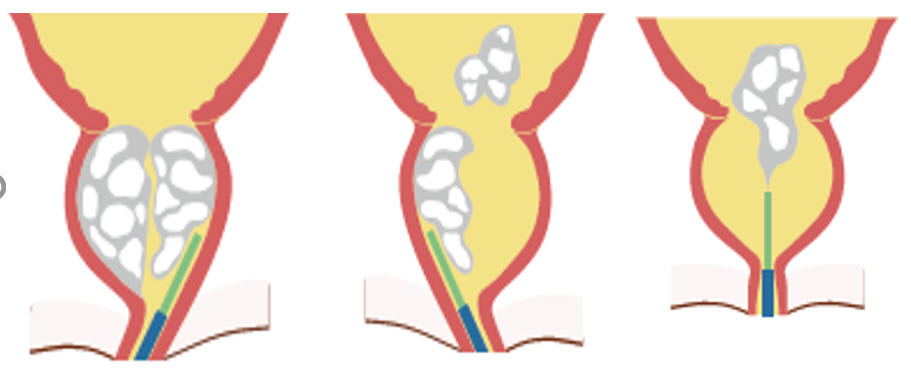

The principle of the Tissue sensor is that the laser distinguishes which tissue (hard or soft) is in front of the fiber. Thus, during lithotripsy, the laser automatically stops emission of radiation when pointing at the mucosa, eliminating the risk of damage. There are no analogues of the Tissue sensor in the world!

There are no analogues of the Tissue sensor in the world!

Percutaneous nephrolithotripsy

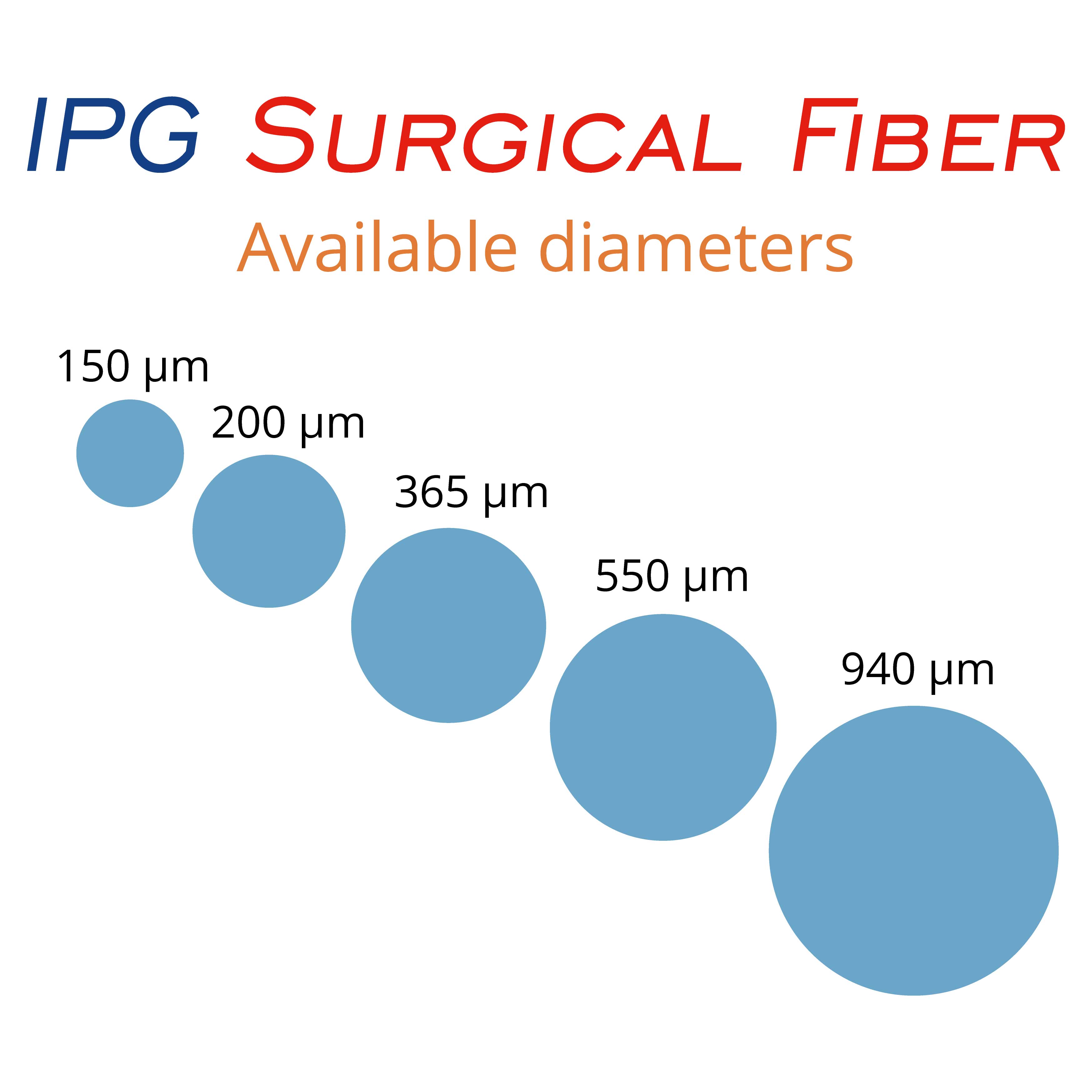

550 µm fiber

Density = 1640 HU

Parameters: 3 J x 13 Hz = 39 W

Examination of mucosa after crushing

- no signs of damage

The pedal for switching on the radiation is always kept pressed!

ALL TYPES OF LASER LITHOTRIPSY:

from the fine dust to large fragmentsв

Modulated pulses

Modulated pulse settings of the Urolase+ and Urolase+ Premium lasers allow lithotripsy in various modes: from "dust" crushing to breaking into large fragments for lithoextraction and lithoevacuation.The use of the new "Fine" mode allows the surgeon to crush the stones into the finest dust at high speed.

REVOLUTIONARY NEW FRAGMENTATION MODE "ULTRA" «ULTRA»

The special pulsed fragmentation mode "Ultra" instantly breaks down the densest stones into large fragments for subsequent lithoextraction.

ADVANTAGES OF THE NEW "ULTRA" FRAGMENTATION MODE

- HIGH FRAGMENTATION SPEED

- EFFICIENCY COMPARABLE TO ULTRASONIC LITHOTRIPTERS

- REDUCED OPERATIVE TIME

- 100% STONE FREE RATE

Transurethral cystolithotripsy

60 J x 1 Hz = 60 W

Percutaneous nephrolithotripsy

30 J x 1 Hz = 30 W

Transurethral ureterolithotripsy

3 J x 3.5 Hz = 10.5 W

TWO TYPES OF ENUCLEATION WITH UROLASE + PREMIUM

CLASSIC THULIUM FIBRE ENUCLEATION (ThuFLEP)

"DISSECT" - THERMO-MECHANICAL DISSECTION MODE

"DISSECT" - THERMO-MECHANICAL DISSECTION MODE

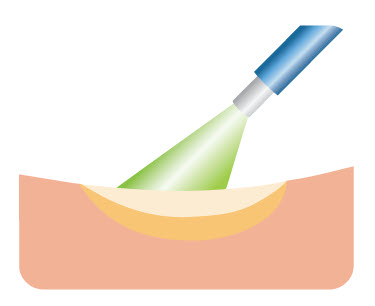

- EFFECTIVE VAPORISATION OF SOFT TISSUE

- PRECISION WORK, DUE TO THE MINIMAL PENETRATION DEPTH

- NO BLOOD LOSS DUE TO EXCELLENT HAEMOSTASIS

- NO CARBONISATION

- DISSECTION OF ADENOMATOUS TISSUE IS SIMILAR TO THE CLASSICAL HOLEP PROCEDURE

- HAEMOSTATIC PROPERTIES SIMILAR TO THUFLEP

The Urolase+ lasers integrate an innovative prostate enucleation mode, which is based not only on pulse energy and frequency parameters, but also on computer modulation of each pulse.

At the same time, the lasers will retain the ability to operate on the FiberLase U1 and FiberLase U3 parameters.

Classic ThuFLEP mode

(1.5 J x 40 Hz = 60 W)

“Dissect” enucleation mode

(2.5 J x 24 Hz = 60 W)

UNIQUE MODES OF UROLASE + OPERATION ON SOFT TISSUE

“Bloodless” coagulation mode

Urolase+ has a unique pulse mode for coagulation. Due to the wide exposure area, this mode allows effective coagulation of the postoperative bed from a short distance.

RIRS: stone in kidney

1 J x 22 Hz = 22 W

THE UROLASE + LASER USES A ONE PUSH FIBER INSTANT CONNECTION FOR EASY PLUGGING

NO NEED TO SCREW THE FIBER ON

| Urolase+ | Urolase+ PREMIUM | |

| Wavelength, µm |

1,94 |

1,94 |

| Laser type | Tm fiber | Tm fiber |

| Operating mode | Pulsed, CW | Pulsed, CW |

| Maximum power, W | 40 | 70 |

| Pulse Energy, J | 0,02 ... 6 | 0,02 ... 6 |

| Frequency, Hz | 2000 | 3500 |

| Cooling system | Air | Air |

| Supply voltage, V | 220±10 | 220±10 |

| Frequency, Hz | 50 … 60 | 50 … 60 |

| Power consumption, V-A not more than |

1600 |

1600 |

| Dimensions (H*W*D), mm |

606*526*314 |

606*526*314 |

| Weight, kg |

45 |

45 |

In addition to the standard X-Y-Z axes and laser process head, there are several optional modules and accessories that may optimize the functionality of the system in your specific application. Below are some of the the most popular options.. Please contact IPG directly if you have additional requirements

Rotary Stage, A or

C axes, Direct Drive

High-precision, high-speed rotary stage with continuous motion synchronized to X-Y-Z axes

- Servo-driven rotary stage

- Brushless direct drive.

- Travel +/- 360° continuous

- Rotation speed: 600 rpm max

- Accuracy: 10 arc-sec

- Bi-directional repeatability: 4 arc-sec

- Pneumatic ER25 Collet Chuck

- Includes an additional axis of motion control

Rotary Stage, A or C axes, Gear Drive

Rotary stage with continuous motion synchronized to X-Y-Z axes

- Servo gear/belt-driven rotary stage

- Travel +/- 360° continuous

- Rotation speed: 30 rpm max

- Accuracy: +/- 180 arc-sec

- Bi-directional repeatability: +/- 45 arc-sec

- 5C Collet, 3 Jaw Chuck

- Includes an additional axis of motion control

Rotary Stage, B axis, Gear Drive

Rotary stage with continuous motion

- Servo gear/belt-driven rotary stage

- Travel +/- 90° continuous

- Rotation speed: 30 rpm max

- Accuracy: +/- 180 arc-sec

- Bi-directional repeatability: +/- 45 arc-sec

- Includes an additional axis of motion control

Coaxial Viewing Package

Camera system aligned with laser beam axis.

- Coaxial viewing system is integrated into laser head to provide live feedback on part positioning

- Package includes software with crosshair generator to display video feed

Power Meter

Laser power meter with stage-mounted detector for periodic verification of power on target. Useful for verifying performance of process head optics and coverslide.

Fume Extractor

- High flow-rate fume extractor for collection of smoke, fumes and air-borne debris.

- Flow rate of 380 m3/hr (220 cfm)

- 3-Stage filtering

- Reverse flow filter technology

- Real-time airflow reading

- Remote diagnostics

Automatic Doors

- Pneumatic actuator to automate slide door which can be controlled via HMI software or G-code

Multi-Axis Workstation Software

The Multi-Axis family of workstations are high-accuracy platforms designed to take advantage of the high beam quality found in IPG’s fiber lasers. Systems can be configured using any IPG laser, with laser processing heads available for welding, cutting and scanning applications. System options can include both basic and smart vision packages, along with part identification and process verification hardware.

The Multi-Axis software integrates control of the laser, motion systems and all system components to provide easy programming of the tool using G/M code commands that are familiar to CNC machine programmers.

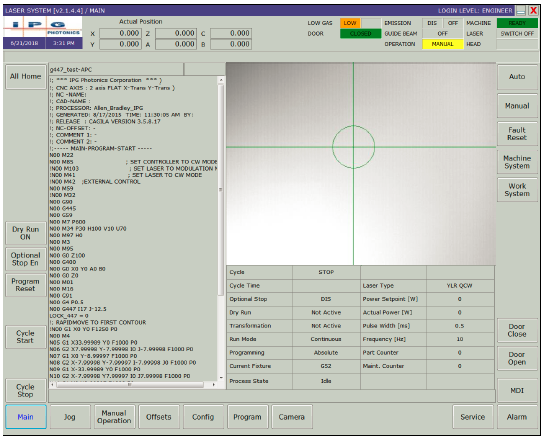

HMI (Human Machine Interface)

The software that runs the Multi-Axis Workstations is a customized application called HMI (Human Machine Interface) that runs as a Microsoft Windows® 7 application. It is preloaded and tested at the IPG factory and resides in the workstation’s hard drive.

The HMI program consists of four primary regions:

- System Status Indicators – Providing a constant overview of the machine status, regardless of function selected

- Function Selection Bar – Providing primary selection of module operation

- Function Control Interface – Allows intuitive set up of configuration and operating parameters

- Manual Control Bar – Enabling manual operation of the systems global functions

Three Password-Protected Levels of System Control: Engineer, Maintenance and Operator.

User screens enable the Engineer, acting as system administrator, to easily set permission levels for each HMI screen for each level of operator and set corresponding passwords.

The system can operate in manual or programmed mode, and has functions to enable Dry-Run (execution of the full program but with the laser not turned on) and Optional Stop – that will allow a pause in the processing cycle for part inspection and other uses.

Used in combination with standard G-code programming, these capabilities provide the user with a comprehensive, easy-to-use programming and operator interface.